H-VISIONS FMCG Industry Intelligent Manufacturing Platform

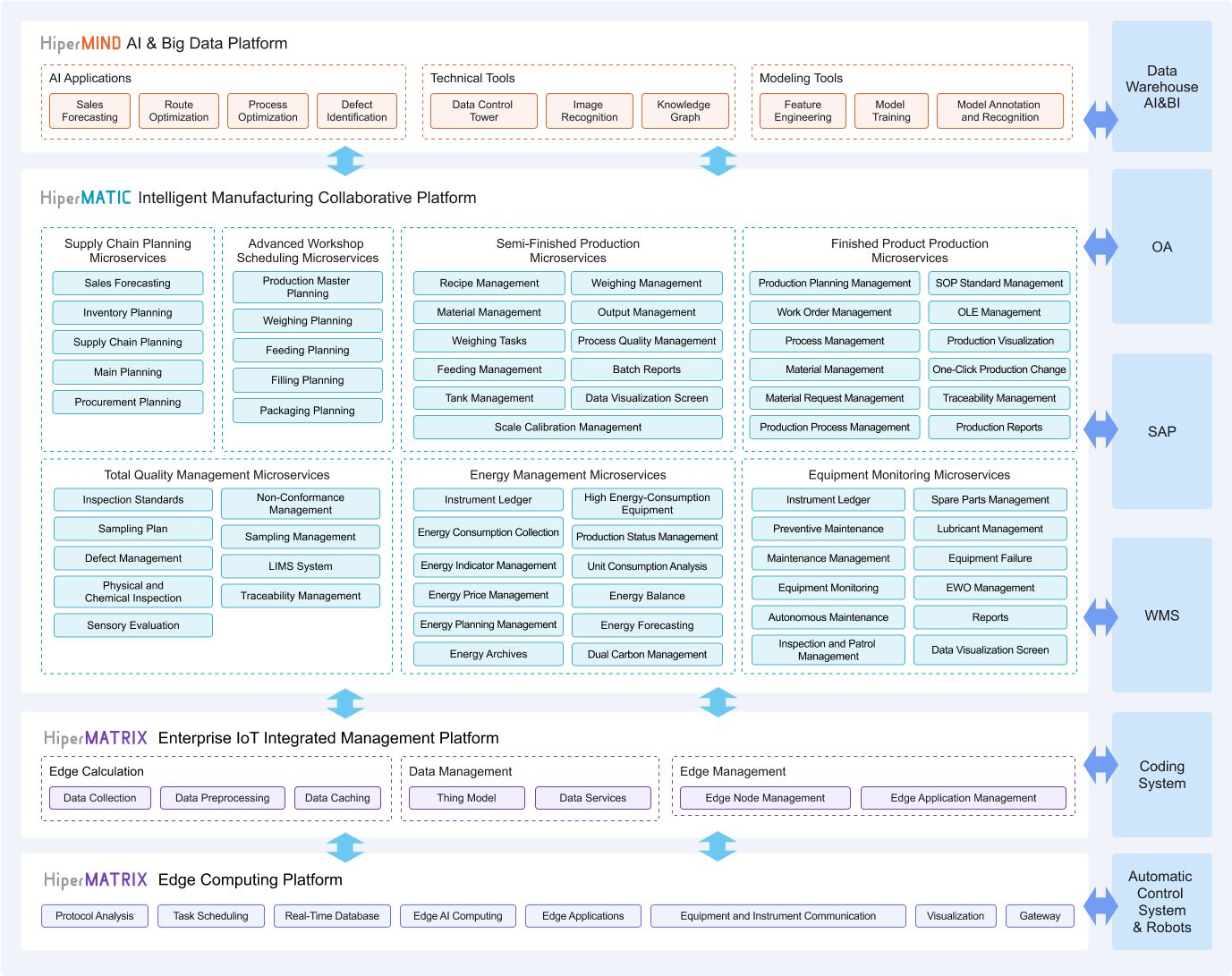

Delivers refined process control for semi-finished and finished product manufacturing in the food, beverage, personal care, and tobacco sectors. Our solutions encompass supply chain planning, production scheduling, materials management, equipment oversight, quality assurance, energy management, and personnel coordination, empowering companies to establish 'Lighthouse' intelligent factories within their industries

Consult Now →Value of HiperMATIC FMCG Suite

Why Do Many Leading Automotive Companies Choose H-VISIONS' Solutions?

H-VISIONS FMCG Industry Intelligent Manufacturing Platform

H VISIONS Full-Stack Smart Manufacturing Solutions for the FMCG Industry

客户案例

- Taicang Unilever Ice Cream

- Unilever

- Mars Wrigley

- P&G

- WEI Beauty

Partnering with Taicang and Unilever to Create the World's First "Lighthouse Factory" in the Ice Cream Industry

As a global FMCG company, the Taicang Unilever factory has been recognized as a "Lighthouse Factory" by the Davos World Economic Forum and McKinsey, representing the highest level of intelligent manufacturing and digitalization in global manufacturing. The factory leverages technology to empower ice cream production and innovation, utilizing AI models, consumer-oriented digital innovation tools, flexible production lines, and full automation to integrate the entire end-to-end value chain.

Collaborating with Unilever Tianjin to Establish the World's First "Lighthouse Factory" in the Condiments Sector

The Tianjin Unilever factory has also been recognized as a "Lighthouse Factory," and it is the only condiment "Lighthouse Factory" globally. The factory empowers product production and innovation through AI models, digital innovation tools, flexible production lines, and full automation, connecting the entire value chain.

Teaming Up with Mars Wrigley to Achieve a Fully Integrated Smart Factory with "Three Innovations and Three Centralizations."

Mars, as a leading global food manufacturer, drives digital transformation in its factories through continuous improvement and innovation. Mars' "Lighthouse Factory" embodies its "The Future Starts Now" approach by implementing synchronized supply chains, intelligent production processes, and traceable quality. This strategy has led to centralized management, information, and operations—its digital transformation strategy of "Three Concentrations."

Working with Procter & Gamble to Build a Fully Automated Smart Factory

As the largest FMCG company in China, with annual sales exceeding $2 billion in Greater China, P&G's leading brands, such as Head & Shoulders, Rejoice, Safeguard, Olay, Pampers, Tide, and Gillette, dominate their respective markets. Through automation upgrades and the development of digital factories, P&G has achieved flexible production, batch processing, tank management, cleaning, and comprehensive digital production process management.

Collaborating with WEI Blue Beauty to Jointly Develop a Fully Integrated Smart Factory

WEI Beauty is a modern Chinese medicine skincare brand under the Fosun Group, established in the early 1990s in Pennsylvania, USA. The brand draws inspiration from ancient Chinese medicine, blending precious herbal ingredients with modern formula technology. Its concept, "Han Fang New Works, Nurturing You," reinterprets traditional Chinese medicine to make it more relevant and understandable for today's consumers. The Hiper series products connect the ERP system to the semi-finished product input process, covering warehousing, weighing, input, and output. This integration enhances industrial IoT, manufacturing collaboration, and artificial intelligence applications.