Smart Manufacturing Management Platform for Beverages

Provides a digital smart manufacturing solution for beverage companies, covering the entire business chain from fermentation, brewing, blending and storage to bottling and packaging. This platform aims to enhance production efficiency and quality management across the enterprise.

Consult Now →Value of H-VISIONS HiperMATIC Beverage Industry Suite

Why Many Beverage Enterprises Choose H-VISIONS Solutions

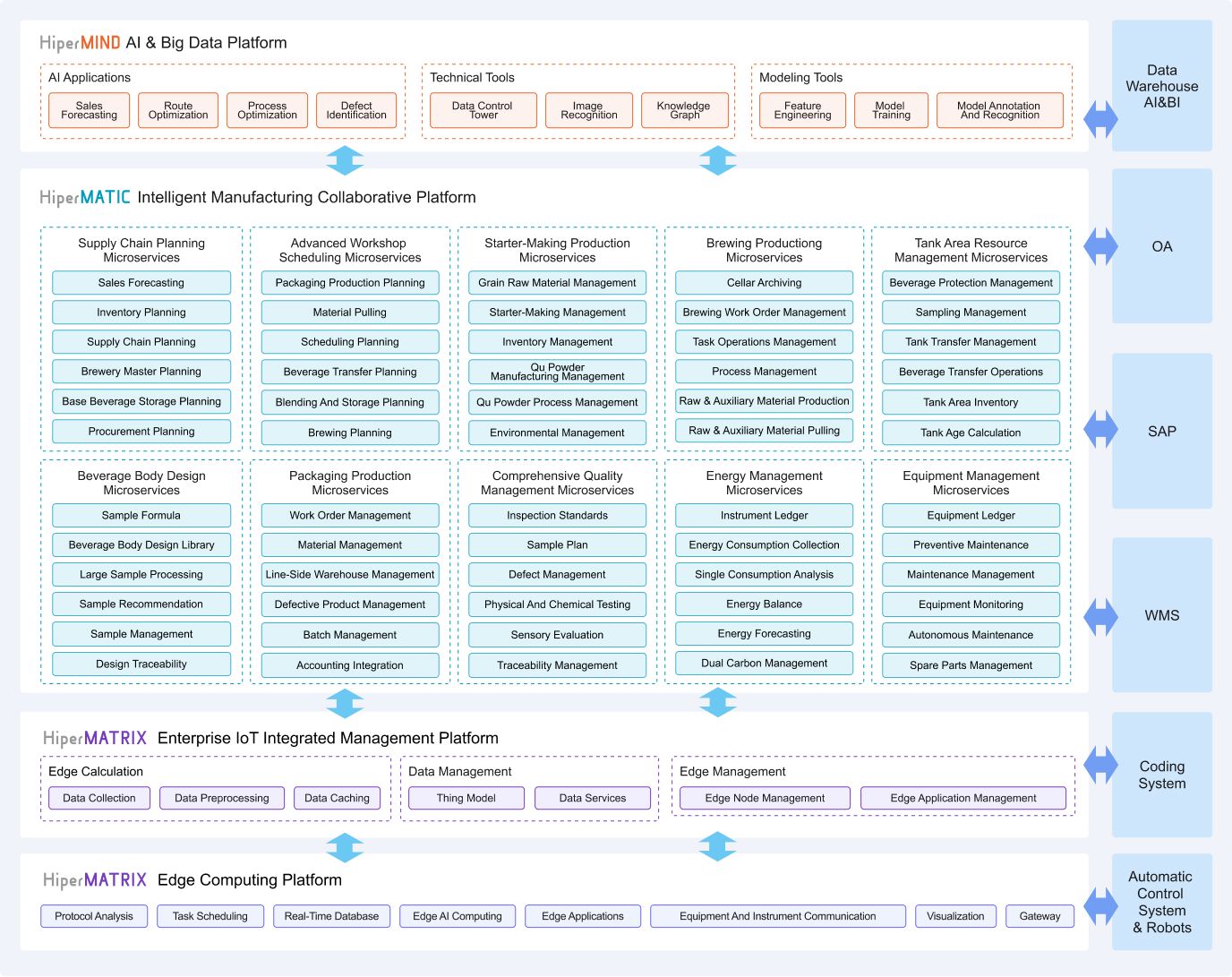

H-VISIONS Beverage Smart Manufacturing Management Platform Solution

H-VISIONS Full-Stack Smart Manufacturing Solutions for the Beverage Industry

客户案例

- Kweichow Moutai

- Luzhou Laojiao

- Yanghe Co.

- Shede Spirits

- Guizhou Zhenjiu

Partnering with Kweichow Moutai to enable digital supply chain management

Following the "Smart Moutai" plan, the supply chain management system ensures the supply of base liquor and packaging materials, streamlines production processes, integrates data, and enhances information support, advancing the "Smart Moutai" goals. Using H-VISIONS HiperMATRIX IoT platform to integrate OT and IT systems, it builds a comprehensive data foundation. The HiperMATIC platform enables supply chain collaboration in production packaging, leveraging technology to create sustainable value for Kweichow Moutai.

Collaborating with Luzhou Laojiao to establish a digital "Fragrant Lighthouse."

By leveraging H-VISIONS Hiper products and the beverage industry suite, Luzhou Laojiao achieves end-to-end value stream integration across brewing, fermentation, and packaging, with a focus on planning, quality, production, and materials management. Centered on information technology, the company efficiently coordinates smart packaging and brewing equipment, establishing a smart manufacturing lighthouse factory for the beverage sector. Additionally, through big data and AI technology, Luzhou Laojiao enables the "digital inheritance" of the Guobao fermentation pits.

Working with Yanghe to create a fully integrated smart factory

Yanghe Co. has pioneered supply chain innovation, creating an integrated, digital, and intelligent factory. HVISIONS played a key role throughout the digital transformation process, offering consulting, needs assessment, blueprint planning, software design, hardware modification, and implementation. This facilitated comprehensive digitization from brewing to packaging, enabling Yanghe to establish an intelligent production and operations platform across its three major facilities.

Joining forces with Shede Distillery to develop a traceability system for aged liquor

In the critical areas of brewing, tank management, liquor design, and packaging, batch mixing, complex data, and traceability pose significant challenges for the industry. Drawing on its extensive experience and successful projects in the beverage sector, H-VISIONS utilized the HiperMATIC beverage suite to establish a traceable system for aged liquor. This foundation enhances Shede Spirits' quality safety traceability and supports its aged liquor strategy.

Teaming up with Zhenjiu Group to implement a comprehensive quality management system.

Guizhou Zhenjiu has significantly increased its production capacity, ranking among the top three beverage companies in Guizhou. To maintain its high-quality standards, Guizhou Zhenjiu utilizes the H-VISIONS HiperMATIC QMS platform for digital support in quality system management, process control, improvement feedback, and operational decision-making. By managing core quality data related to processes, physical and chemical properties, and sensory evaluations, the platform enhances liquor quality and yield, ensuring controlled quality safety and continuous improvement.