H-VISIONS Automotive Intelligent Manufacturing Management Platform

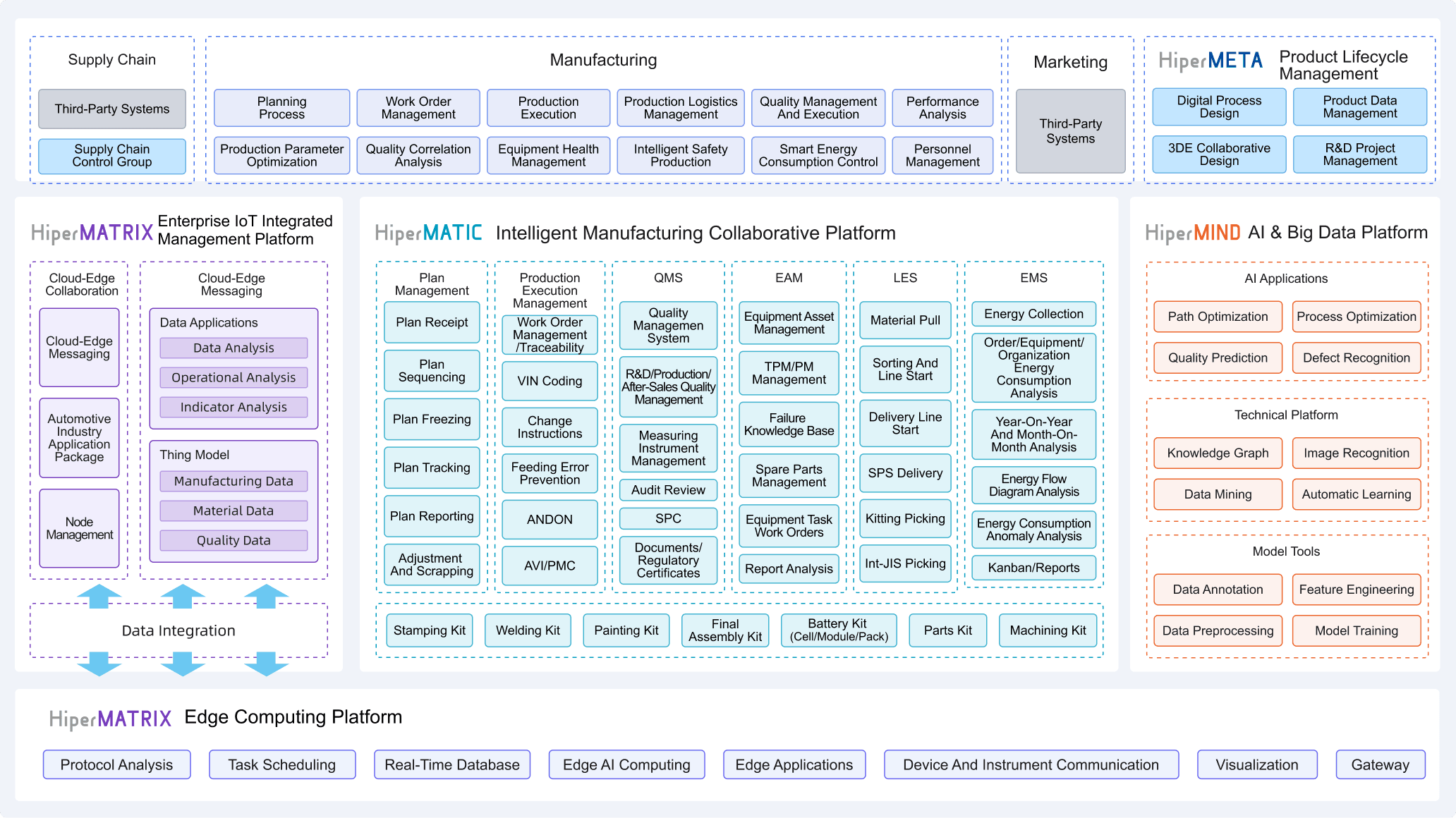

Leveraging the HiperMATRIX IoT, this platform delivers a comprehensive, data-driven solution for the automotive manufacturing industry. It facilitates a new generation of digital manufacturing operation management that is flexible, transparent, interconnected, and intelligent, optimizing every aspect of the automotive manufacturing process.

Consult Now →The Value of H-VISIONS Automotive Industry Suite

Why Do Many Leading Automotive Companies Choose H-VISIONS' Solutions?

H-VISIONS Automotive Intelligent Manufacturing Management Platform Solution

H-VISIONS Full-Stack Architecture Solution for Automotive Industry Intelligent Manufacturing

客户案例

- FAW Hongqi

- SAIC Motor Passenger Vehicle

- Chery Automobile

- GAC Honda

- Neta Automobile

Mastering Key Core Technologies, Establishing a National Automotive Brand

With the goal of "establishing a national automotive brand and creating a world-class automotive enterprise," FAW Hongqi leads brand development through innovation, keeping key core technologies firmly in its hands. In the construction of the new energy battery and electric drive new base project, the H V-ISIONS HiperMATRIX IoT platform is used to build the factory manufacturing data foundation. Additionally, the H-VISIONS HiperMATIC automotive industry suite - Central Control System is employed to intelligently manage the production of new energy electric drive systems. By focusing on achieving On-Time Delivery (OTD), a comprehensive digital twin of the entire production, quality, and equipment process is realized, ensuring high-quality product delivery. This effort writes a new chapter of exclusive excellence.

The first automaker to pass CMMM Level 4 assessment

As an exemplar of intelligent green factories, the SAIC Motor Passenger Vehicle Ningde Base has created an integrated system of "intelligent equipment," "smart supply chain," and "big data intelligence," earning the title of "China Benchmark Intelligent Factory" in 2020. Using the H VISIONS HiperMATIC automotive industry suite, it covers the entire vehicle manufacturing value chain, including stamping, body, paint, and assembly, integrating industrial IoT, manufacturing collaboration, and AI applications.

Partnering with Chery Automobile to Create Powerful Engines

Chery's new fourth-generation engine assembly line uses the H VISIONS HiperMATRIX IoT platform to connect upstream information systems with downstream equipment, supporting production needs. The HiperMATIC manufacturing collaboration platform enables comprehensive digital management of production, processes, equipment, and quality, covering the entire production process from order receipt to completion.

Every Car is Delivered to Users with Peace of Mind and Quality

With 25 years in the Chinese market, GAC Honda has earned the trust of nearly ten million car owners and topped the J.D. Power China Initial Quality Study for mainstream brands for three consecutive years. To ensure every car meets high-quality standards, thousands of detailed inspections are performed in the workshop. Using the H VISIONS HiperMATIC QMS quality management system, quality operation guidance is automatically pushed to terminals, and defect information entry time is reduced to under three seconds. This system has achieved paperless inspection records, ensuring timely data sharing and intelligent analysis, effectively guaranteeing vehicle quality.

Partnering with Hozon Auto to support Nezha Auto's overseas production

Hozon, the parent company of Neta Auto, integrates innovative technology development, intelligent production, and omni-channel sales services. H VISIONS helped Neta build an integrated intelligent manufacturing solution from parts to complete vehicles. This includes establishing enterprise standards for modules, processes, and system integration, and applying these standards across multiple domestic and international production bases, achieving comprehensive digitalization of multi-factory manufacturing operations.